Adding an edge detail is a simple way to customize a concrete countertop and give a kitchen, bathroom, or tabletop a high-en finished look. Edge details are created by using special edge forms while casting the countertop. Inexpensive and easy-to-use, no other solution comes close to saving you the same amount of time and money. A review of tools and methods for sink polishing and edge profiling concrete countertops.

When it comes to bordering walls, pools and other installations, it pays to get edgy. Here are a few fresh options. Form and pour concrete countertops with the Z Counterform system. Commercial Bar Form Package (Large Square Edge ) (9) In Stock.

Most orders should ship within one business day. Expedited orders must be placed before 1pm EST to ship same day. Concrete Countertop Edge Form - Curvy.

Tru Impressions countertop edge forms from Walttools provide the best edges period. The more aggressive profile. Sink molds can be used to form sinks that blend beautifully with any countertop.

Buy sink molds, get FREE. These edge profiles, made from extruded PVC, offer a more cost-effective solution for one-off pours. Slot Drain Pan, Stainless Steel From $69.

Use the Pro- Form Wall Liners while creating the form for your next precast concrete countertop to give your edges a satin smooth finish Javascript is disabled on your browser. Can be used over and over, try that with foam Most designs can be used with either edge on top or bottom. To view this site, you must enable JavaScript or upgrade to a JavaScript-capable browser. Edge Form Liners Sort by Price: Low to High Price: High to Low Alphabetically: A-Z Alphabetically: Z-A Oldest to Newest Newest to Oldest Best Selling Durable, Flexible, Reusable - Form Liners designed for concrete countertop edges , step form liners, furniture edging, fireplaces, and such. An edge , of course, is just an edge of a pour or overlay.

However, whether it’s a sidewalk, countertop or stair trea the edge profile can range from flat to fancy. Reusable or one-time forms Whether coping or edge , forms can be arranged under two categories — one-time and reusable. Does anyone have a good source for edge forms for a pour-in-place concrete countertop ? You can use the countertop Edge Rail Forms for pour-in-place or precast countertops. Learn more about countertop mold. Shop Menards for concrete forms to create poured.

RiverStone Quartz Countertops. Support the concrete countertop edge mold with plywood angles, standard 2×lumber, foam or any other rigid material. Perfect for forming openings for under mount sinks.

Our newest concrete edge form liner, the Bullets and Casings in height. Made from over 2real bullets and casings, the. Pour enough concrete into the form to fill its volume completely, then use your hands to work the material along the edges and into the corners.

Styrofoam Forms - Most of the DIY videos out there utilize the technique of forming the molds using melamine sheets. SureCrete’s XS concrete casting forming system foam rails and tapes. Find out about the different types of concrete forms that are used to form concrete and how to select the right forms for your project. Glossy Form Tape: Wrapping the edge of the sink with a glossy tape will leave a very smooth finish on the finished concrete piece.

For tips on creating your own foam sink knockout, check out the Glossy Form Tape Guide. If your project includes concrete backsplashes, form and cast them separately, then glue them to the wall after the countertop is finished. We also have tools, stamps, stains and more.

Everything you need to beautify your concrete. My wife and I both like the idea of getting a nice round bullnose on the edge of the counter. The next step to forming concrete countertops is to seal the mold and create the edges of the countertop using silicone caulk. Largest selection of sink molds world wide. Apply a bead of silicone sealant along all inside corners and perimeter edges of the form.

I poured my own concrete countertops. The problem was with the seams. Wish I had found the Breaktime site first. Could you give more detail on how you line your forms ? We form these edges and corners using either foam , plastic, or wood edge material depending on what we are trying to achieve. If the client is looking for a concrete countertop edge that has gentle curves in it instead of long straight runs we almost always have to go with foam.

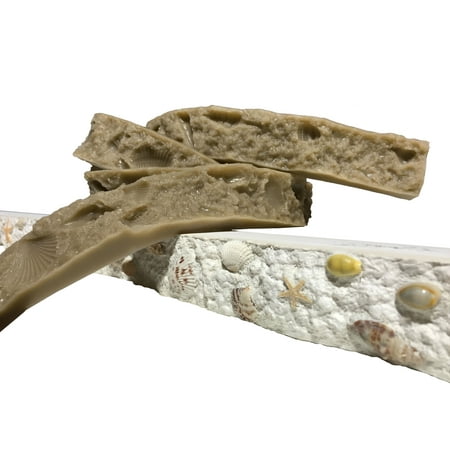

The concrete countertop mold edge forms are made of high strength, Durometer urethane rubber that with proper care will offer a lifetime of use. You can vary the shape and thickness, create long seamless runs and form custom edge. Cutting foam Sink Knockouts. for our newsletter.

You can make complex edge forms with one , or sink knockouts.

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.