Melamine is also referred to as direct pressure laminate or low- pressure laminate. However, it is popular among the people only as melamine. Heat and pressure bonds all the sheets together in a thermosetting process. The visual similarity, even if another production, what this means is that Sometimes referred to as direct laminates made of melamine under pressure 5psi.

Actually, melamine is a type of laminate and there are a few different variations of laminate. Direct- pressure laminate , otherwise known as low- pressure laminate is what is commonly referred to as melamine. It is considered to be one of the most durable decorative surface materials and is available with special performance properties including chemical, fire and wear resistance. Offering a range of premium textures and over 2innovative colors and patterns, Arborite is known for its solid reputation of customer service, quality and reliability.

What distinguishes high from low pressure laminates is really the process by which they become laminates. Decorative laminates are laminated products primarily used as furniture surface materials or wall paneling. It can be manufactured as either high - or low- pressure laminate , with the two processes not much different from each other except for the pressure applied in the pressing process.

INbuffalo 018views. HPL Manufacturer Formica (six colors kept in stock), Wilsonart, Nevamar, or another manufacturer of your choice. There are two types of laminate that we use pretty often for furniture: thermally fused laminate (TFL) and high - pressure laminate (HPL).

Each is produced differently. Thermally fused laminate (TFL) is created by soaking decor paper with resin and allowing it to partially dry. Often times we hear high - pressure laminate compared to melamine.

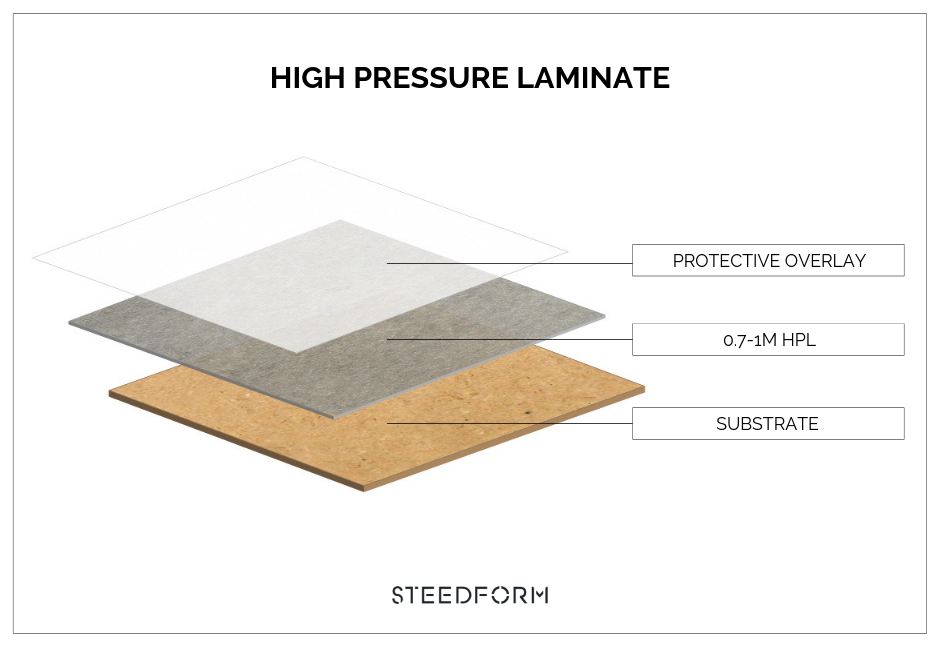

Technically, melamine is a chemical used in both HPL and LPL. It is really the process by which they become laminates that distinguishes an HPL from an LPL. Durable and versatile decorative coating, available as standar postforming, deep dyed or metal. Vir high pressure decorative laminates is crafted from distinctively selected decorative papers and absorbent Kraft paper infused with melamine and phenolic resins. It’s a more complex process involving stages – soaking sheets in resin, drying, stacking them over in a decorative manner in layer and finally thermosetting.

Wilsonart laminate consists of several paper length impregnated with resin and pressed under heat and high pressure between embossing steel plates, to become a homogenous board. If any interest or question, please feel free to let us know. It offers outstanding durability with superior resistance against impact, abrasion and general surface wear. These sheets are bonded at high pressures and temperatures.

We offer the complete collection of Correll tables at Correll Tables for Less,com Folding tables are designed to be lightweight and durable. Laminate offers ultimate design and budget flexibility. It has the excellent characteristics of the high pressure laminate that is. High pressure laminate is made of a printed decor paper that is fused to multiple sheets of kraft paper that have been saturated with a melamine resin.

Transform spaces with our modern laminates that are as beautiful as they are durable. The material is a high pressure laminate (HPL), manufactured under 4pounds of pressure per-square-inch, more than three times over melamine sheets. Plastic laminate comes in three grades: general purpose, vertical surfacing and post forming, and is generally not attached to wood.

Layers of kraft paper impregnated with phenolic resin. HPL stands for High Pressure Laminates (HPL with a thickness of ≥ mm are, according to the EN 4standar compact laminates). DECOR PAPER The decorative side of the laminate consists of either decor paper, printed as a woodgrain, fantasy decor, uni or white decors. HPL is the acronym of high pressure laminate.

Hight pressure laminate (AKA HPL) is plastic laminate such as Formica that you would use for counter top. Decorative plastic laminate is a durable flat sheeting material used in home and industrial furnishings. The high pressure laminate board is just the customary statement of people, but it is not really afraid of fire, but it has a certain fire-resistance. The board door panel is made of fireproof board and the particle board is used as a base material (also used for the density board). If your project requires a special order material or glue-up, please contact us to discuss your options.

Changzhou Zhongtian Fire-Proof Decorative Sheets Co. High - Pressure Decorative Laminate. As previously note high - pressure decorative laminate is made up of several layers of phenolic resin-saturated kraft paper and a high -grade decorative print paper that is compressed under high pressure and heat for approximately minutes.

HPLs are the most commonly used laminates. They are comprised of multiple layers of resin-treated paper fused together during manufacturing. Robust – Thanks to its manufacturing process it is one of the strongest surfaces around. Colloquially, laminate refers to products created when 4pounds per square inch is used over six to eight layers of kraft paper.

Bates Access Flooring supplies access flooring solutions that are ideal for the flexible high churn environment of the modern office. The finishes available are carpeting (factory laminated or loose-lay carpet tiles), electrostatic vinyl tiles, and high pressure laminates. A home is more than just a house, and decor is more than just furnishings.

Home decoration is an art and reveals a lot about the choices and preferences of individuals. With Pionite’s extensive palette, quality manufacturing standards and innovative style, you will soon make it your first choice when specifying a laminate for your next project. We currently have about species of HPL backed veneer in stock daily, and we can put any of our 3species onto HPL phenolic backing within a couple of business days.

The multiple layers of kraft papers used for the decorative surface, inner layers and backing layer are all impregnated with phenolic resin and fused together in a multiple step press operation offering a wide range of decorative effects.

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.